Sep 29, 2021

How to reduce long lead times in your supply chain

Reducing long lead times in your supply chain is a critical step to meeting your customer demands on time and reducing inventory costs.

In today's fast-paced and highly competitive environment, inventory planners face ongoing pressure to achieve the balance of ensuring the right amount of stock is procured to meet customers’ expectations while not incurring additional costs to the business.

The unpredictable nature of supply and demand right now means you need to have complete visibility and understanding of each link in your supply chain. More than often, the weakest link is the impact of long lead times on your inventory.

Findings from the recent survey conducted by the Institute for Supply Management's Manufacturing [ISM] Business Survey Committee highlights “Extended lead times are particularly affecting electronic supplies, which includes semiconductors. One respondent to ISM's June 2021 Manufacturing Report on Business said lead times for electronic components went from 16 weeks to more than 52 weeks.”

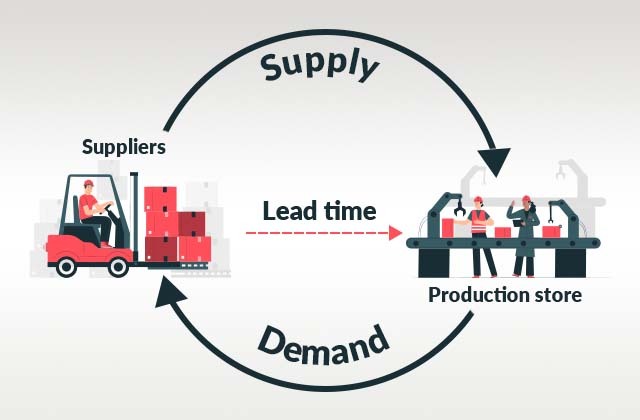

You can only achieve an effective supply chain through collaboration.

Your key focus should be gathering information from your supply and demand, analyzing that information, and then applying that information to take action and make the best possible decisions for your inventory.

There are two approaches to reducing your lead times:

- Knowing the pressures and constraints your supply and demand are facing and using that information,

- and reviewing your inventory processes to make the necessary changes to adapt and optimize your supply chain.

What is inventory lead time?

Inventory lead time is the length of time from when you place a purchase order with a supplier, taking into account the internal processes such as waiting for approval to place the order to when the order is available for sale to the customer. Your lead time will affect your overall inventory fill rate, i.e. your ability to service your customer with the current stock you have on hand.

From placing the purchase order and until the stock arrives safely to the customer, inventory planners need to be aware of additional delays and how these will affect your lead time.

Supplier lead time

The time from when the supplier receives the purchase order to when the order is shipped.

Production lead time

It is the time from when the raw materials are requested from your warehouse to when it is available for production. Production disruptions such as a shortage of materials or labor shortages at the assembly stage can increase lead times and be extremely costly for your business.

Note: Raw materials with extended lead times must be planned and ordered in advance. A demand planning solution is the best tool to help your business effectively prepare for this.

Delivery lead time

The delivery lead time is the length of time it takes to collect the finished product from the dispatch bay to deliver the stock to the customer. Internal disruptions can also impact long lead times during this process. Suppose the customer order is not an "over-the-counter sale." In that case, the process of capturing the customer's order, allocating the stock, picking it, moving it to the dispatch bay, preparing for delivery, and raising the delivery note are components where delays can occur. External disruptions also happen during this process, such as transport congestion, delays at ports, or a shortage of trucks due to high demand for products will affect your stock arriving on time.

How do you calculate lead time?

When do you need to factor in lead time into your inventory planning?

When you are calculating:

- Reorder level.

- Cover forward or order-up-to quantity.

- Safety stock.

What is lead time performance, and why is this so important in your supply chain?

Lead time performance measures the supplier lead time based on early or late order deliveries. Given that lead times are essentially an external variable determined by your suppliers, you don’t have 100% control over this. It is therefore critical to monitor and measure the lead time performance of your suppliers.

To measure lead time performance, you need to have two processes in place:

- You need a software tool to help monitor your supplier’s lead times.

- A mechanism to quickly update the new lead times in your system.

All stock items will have an allocated supplier, which means each supplier will have its own specific lead time. If you are sourcing a particular stock item from more than one supplier, that item will have more than one lead time. If your supplier consistently delivers stock late, this will impact the amount of safety stock you need to meet your demand and increase your inventory costs.

What causes extended lead times?

As mentioned, while you don't have control over your supplier's lead times, inventory planners, operations, and sales teams must be aware and remain up to date on the disruptions taking place across their supply chain and how that can cause increased lead times.

Here are a few examples of disruptions that will affect supplier lead times:

- Erratic customer demands

- Shortage of raw materials

- Shipping delays

- Shortage of cargo containers

- Labor shortages

- Natural disasters such as fires and hurricanes.

- Trade wars

According to the Precision Metalforming Associate [PMA], “Members are experiencing ongoing challenges particularly in finding the raw materials needed to meet demand, with some members expecting steel lead times to extend into midyear of 2022,” said PMA President David Klotz. “Lead times also are lagging for aluminum, copper, brass and other metals. Add to that the lingering impacts of the pandemic including the difficulty in finding and maintaining skilled workers and our members are facing a complicated landscape”.

Let’s explore five practical solutions that can help you reduce lead times in your supply chain today.

1) Classifying your inventory will help identify the items that make the most significant contribution to your business.

Regardless of the size of the inventory you are managing, a vital step to help reduce the impact of lead times on your inventory is to know which stock items you need to focus your attention on. We talk about the 80/20 rule a lot in managing inventory. You can focus on the 20% of your SKUs [stock-keeping units] that give you 80% of your sales by classifying your inventory.

So, how will classifying your inventory help reduce the impact of long lead times? You will save yourself time and resources by prioritizing suppliers for your key products so that you can:

- Regularly review projected lead times on these critical products with suppliers before you place the order.

- Group your essential products, with similar lead times, into categories with common delivery characteristics such as the same delivery lead time and lead time reliability. This will help you review essential stock items as a group instead of having to view each item’s lead time.

- Avoid using historical data for average lead times for a single line item. By grouping your lead times, you can then use this data to continually upgrade and refine the expected lead time of the group of items as a whole.

- By identifying your key products, you can negotiate with the relevant suppliers to hold enough stock of these products for you.

Watch how NETSTOCK helps classify your inventory.

2) Work with reliable suppliers.

It goes without saying that if you need to adapt your inventory processes to help reduce your lead times, you need a good understanding of who your suppliers are and the challenges they face. Remember: unreliable suppliers can put your business at risk.

- Review how your suppliers perform. You should know immediately which supplier regularly delivers stock late or not in full quantity. With this information, you can review which stock items are impacted and if those items form part of your key product grouping.

- Consider eliminating your unreliable suppliers.

- Communicate regularly with your reliable suppliers. Keep up to date with their pressures and their lead times for the stock items you need.

- Source alternate suppliers and make sure your new suppliers have the stock available to start supplying you immediately.

- Review your terms and conditions and the imposed minimum order quantity or minimum pack sizes with your suppliers.

- Share your sales forecast with your suppliers so they have a clear insight into your planning and can communicate with you immediately should they anticipate any challenges that may impact your stock items.

- An option worth considering is to use air freight suppliers instead of sea freight where possible. Even though air freight may be more expensive, the shorter lead time and lower safety stock level related to that item may result in lower stock holding costs and higher stock turns.

3) Improve your internal and external communication.

Internally with your team.

Managing inventory doesn’t rest solely on the inventory planner’s shoulders. Your planning process requires input from the sales, marketing, and operations departments.

As a team, you should meet weekly to discuss:

- Information about upcoming sales and/or promotional campaigns needs to be discussed ahead of the supplier’s lead time to ensure that the necessary stock is available for these planned events.

- Market intelligence that may affect your suppliers and, in turn, their lead times. If you are starting to hear that there are delays in shipping, you can quickly call your supplier to establish if they will be affected and plan accordingly.

Externally with your customers.

Update your customers immediately if there are going to be any delays with their stock orders. While talking to your customers won't directly help reduce your lead time, it will help with customer loyalty, building trust, and keeping the lines of communication open.

4) Review your order frequency.

The lead time is a critical input to placing optimal orders. It would be best if you considered focusing on ordering a smaller amount of items at a time. The impact of long lead times can then be better managed and ultimately reduce the risk.

If you place bulk orders, you may think you will confidently have the stock you need and not experience any stock-outs. Think about the consequences:

- If you bulk order, you have a large inventory that will incur additional costs like storage, labor, and insurance.

- If this large order is delayed, you will lose sales due to an extended lead time. Your capital will be tied up in inventory that you physically can't deliver to your customers.

- Factor in the minimum order quantity with the supplier. This will affect the replenishment cycle if the monthly demand for the product is below the requirement for the preferable replenishment cycle.

- Identify the stock items below the minimum level after the lead time. If you order those items today, the stock level will be at the minimum level on the day the next shipment arrives from your supplier.

- Calculate the right safety stock needed for each of your key products based on a risk assessment of supplier performance and your forecast accuracy. The longer the lead time, the more safety stock you need to order. Safety stock should buffer you from late deliveries, under deliveries, or under-forecasts.

Ordering strategy. A practical example:

You have an item forecast to sell 100 units per month, every month, and this is your inventory policy:

- Lead time is 20 days

- Safety stock is 15 days

- The replenishment cycle is 30 days

According to the forecast, from order placement until the end of the lead time, you would sell 67 units (20 days at 100 units per month).

Therefore, the safety stock for the item would be 50 units (15 days at 100 units per month), and the trigger to determine when you should place an order can be calculated as:

REORDER POINT = Lead Time (67 units) + Safety Stock (50 units) = 117 units

5) Keep your safety stock levels dynamic in line with changes to your supplier’s lead time.

Holding the correct quantity of safety stock for your high-priority items will safeguard you from the impact of extended lead times from your supplier. Many businesses adopt a set-and-forget mentality and set safety stock to a blanket number to cover for some time. For example, you set your safety stock level for each product item in January, and by September, no one has reviewed that decision. You either have excess inventory or experiencing stock-outs, and your customers are buying elsewhere. You should review your safety stock levels because:

- Your supplier risks change, i.e. their lead times may vary.

- Your forecasts change and or,

- Your business objectives change.

Ideally, you should review your safety stock daily, and to do that, you need reliable automated inventory management software to do that for you.

Do you want greater visibility of your supplier’s performance?

In today’s competitive market, keeping your customers happy is vital. How your suppliers perform directly impacts how quickly you can respond to changes in demand, replenish your stock, and avoid stock-outs.

Let NETSTOCK help you reduce your inventory lead time.

Written by The Inventory Mentor

The Inventory Mentor provides thought leadership insights and industry trends for the supply chain industry.